CRAB II

Versatile platform covers separation of metal radionuclides from the cyclotron targets, their formulation and simple labelling.

New design and technical solution improves the former preconditions of the device which may be smoothly developed to other multifunctional innovation tailored to the customer’s need.

THE SYSTEM COMPRISES

1. External target chute from a cyclotron beam line

- The device enables loading of an irradiated cyclotron solid target in a shielding container in defined orientation (irradiated side up), while minimizing personnel radiation burden.

2. Shielding container

- The shielding container is designed for an easy transport of the irradiated cyclotron solid targets and its loading into the Radiometal Automated Laboratory Workbench.

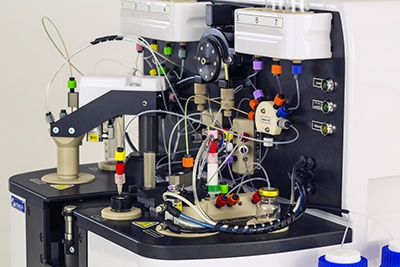

3. Radiometal Automated Laboratory Workbench

- The device performs separation of cyclotron radionuclides from solid or liquid targets and provides their solution suitable for further radiolabelling.

- The whole process is fully automated in order to increase reproducibility and to minimize personnel’s radiation burden. The separation process is based usually on solid phase extraction (SPE) finished by formulation of the separated radionuclide into a desired solvent.

- The system allows for automated performance of simple labelling.

MECHANICAL DESIGN

- Main parts of the RALW: two reactors, two selectors, a peristaltic pump, 3/2 way valves, and a separation column.

- Prime reactor R1 is designed for transport of the dissolved solid target material from the shielding container to the process position and to handle liquid target solution.

- The reactor R1 is leak-proof for 5 bars.

- There are up to four positions for uploading the solvents into the reactor R1 or to the SPE column regarding separations steps.

- The in-built solid phase extraction column for the separation.

- The separation is driven by the peristaltic pump and the solvents.

- The eluent is separated according to the eluted activity profile that is continuously monitored. It allows also for an efficient separation of potentially expensive enriched target.

- Easy adjusting of the final activity concentration according to the particular needs.

- Software controls volume of eluent and allows for setting the final volume without activity loss on the walls of the reactor R2. There are 3 positions for uploading the solvents to the reactor R2 that may be used for formulation or for simple labelling steps.

HARDWARE & SOFTWARE SOLUTION

The system is driven by PLC and I/O cards. PLC is placed outside the module in order to avoid radiation damage.

Connection between module, PLC and host PC is accomplished via an Ethernet cable. This approach significantly decreases number of cables connecting the module with other components in the control chain. PLC is controlled via host PC with friendly user interface. Software is intuitive and stable.

IMPORTANT!

Nearly all the parts of the CRAB can be modified according to the particular requirements of a customer.